Rapid Prototyping to Jumpstart Your Business

What We Do

Our team works with entrepreneurs and companies to take their ideas and concepts to a physical product. This could be a single sub assembly component or the entire project. With expertise in mechanical engineering, electronic engineering, metal fabrication, and go to market strategy, our team of experts can deliver a prototype at a fraction of the time and cost.

Industries we services:

Start-ups

Aerospace

Companies entering the hardware space

Our Services

-

Having issues building a component or struggling on where to begin your journey? We offer industrial and mechanical engineering services to help bring your party to life. This includes 3D modeling, 2 modeling, CAD Design, 3D printing design, and structural analysis.

-

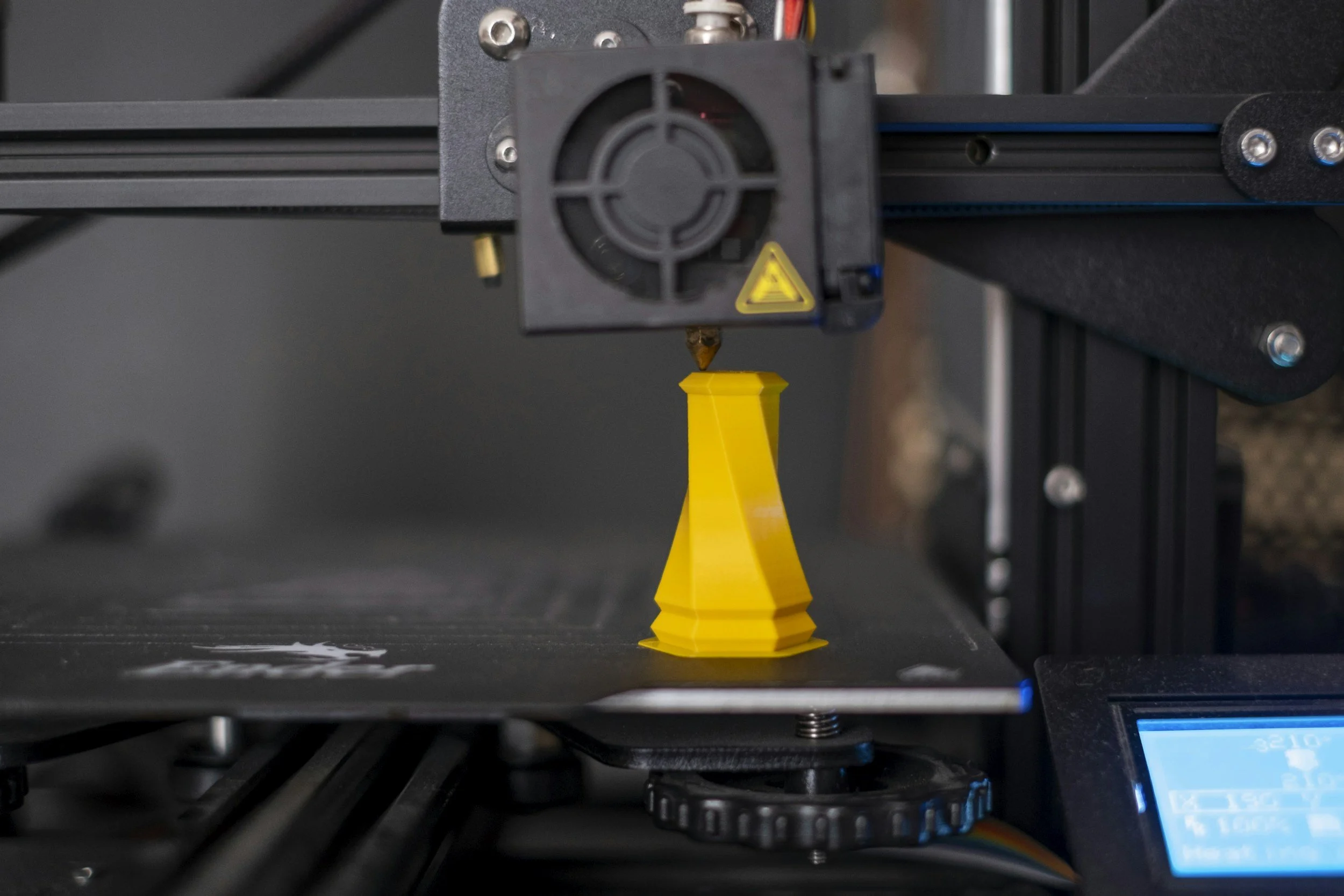

Our clients may have concepts and perhaps drawings but many don’t have machines to build their prototypes and test their components. Our team can actually manufacture components with small runs either through 3D Printing, Vacuum Forming, CNC Machining, or Resin Forming machines.

-

With expertise in electronics, our Electronic Engineers focus on developing PCB boards that will fit your requirements and overall design. In addition, we work with partners that deliver fabricated and assembled boards in expedited timelines.

-

A few of our clients leverage our metal fabricators to build frames, cut steel, or bend tubes. In addition, we offer clients metal fabricated components either through welding, CNC machining, or bending.

-

Finding the right business model to get your product to market is very challenging. Our team has had 3 successful exits and can assist with investor decks, financial modeling, and go to market strategy. This is important for entrepreneurs that are just starting the journey

Our Story

We are a team of 7 (a few folks are missing from this photo) that developed a sustainable appliance by using our expertise in mechanical and electrical engineering, metal fabrication, and a wide variety of hardware knowledge. This prototype is fully functioning washer / dryer combo that recycles water after each wash. It was built primarily using 3D printing and vacuum formed components. We’d be selfish to keep this knowledge and expertise to ourselves. That’s why we decided to help other companies tackle the challenging problems of developing innovative products. Hardware is hard, we want to help.

Schedule today

We love to learn about amazing ideas regardless on how many people told you you’re crazy. We’ve been there, in fact we are developing a product right now and understand the pitfalls of building a hardware product. Feel free to reach out and we’ll schedule a 30 minute session to fully understand where your gaps are in developing this product.